Plastics

Semicrystalline polyammidic polymer with good general characteristics

Features:

- Abrasion resistance: even in dusty or heavy environments, it is among the highest among technopolymers.

- High tensile strength and compression, impact resistance is definitely good especially for non-dry material.

- Fatigue resistance, keeps the features even under repeated strains.

- Self-lubricating, the friction coefficient is low and in principle sliding does not require lubrication.

- Resistance to aging and weathering.

- Antistatic behavior related to moisture absorption.

- EC Food Certification 10/2011 – FDA.

Application:

- Mechanical: Due to its characteristics and cost-effectiveness, it is a ” general purpose ” material widely used in the mechanical industry for gears and cams, pulleys, guides, supports, wear bearings and mechanical parts in general.

- Food: It can be used in contact with food.

- Electrical: The variation of electrical characteristics with the variation of the absorbed humidity strongly limits its use in the electrical sector.

- Chemicals: Resists alkali, inorganic compounds and solvents.

Nylon 6 cast with the addition of molybdenum bisulphide (MoS2), thanks to which it takes on better tribological characteristics. While maintaining the main characteristics of pa6 casting is more impact resistant and more self-clarifying, it works better and resists U-rays better.V.

Features:

- Wear resistance, better than PA 6 G.

- Tensile and compression resistance equal to PA6 G while impact resistance is higher, fatigue resistance is high.

- Self-clarifying, the coefficient of friction is low.

- Resistance to aging, it resists weathering and low temperatures well.

- Black.

Application:

- Mechanical: for the good mechanical characteristics and the possibility of obtaining semi-finished products and semi-finished large pieces is a material widely used for obtaining large diameter gears, pulleys, wheels and wear guides. For excellent abrasion resistance, in construction and earth handling machines it is used for toothed wheels, guides, bearings, supports etc.

In the shipbuilding industry given the best resistance to atmospheric agents it is used to obtain sliding rollers, guides, bushings. In cable car systems for pulleys, wheels, sliding, etc. - Food: it is not usable in contact with food.

- Electric: as the absorbed humidity changes, the electrical characteristics vary; however, it is used when mechanical resistance is required.

- Chemicals: good resistance to alkali, inorganic compounds and solvents.

Polyamide 66 obtained from the polymerization of Hexylenediamine and Adipic acid, having as essential characteristics greater rigidity and wear resistance. It has lower water absorption than pa6 higher temperature resistance; however, it has lower impact resistance and less cushioning power. It is a superior polyammidic resin

Features:

- Wear resistance, even for heavy use.

- Self-clarifying, the coefficient of friction is low.

- Toughness, high tensile and compression resistance, the hardness is higher than that of pa6.

- Easy to work with.

- Resistance to aging and weathering.

- Antistatic behavior related to moisture absorption.

- EC Food Certification 10/2011 – FDA.

Application:

- Mechanics: For the highest rigidity compared to PA6 it is used in the mechanical industry when this feature is preferred at the expense of impact resistance to obtain gears, cams, pulleys, wear guides, wheels and mechanical parts in general.

- Food: It can be used in contact with food.

- Electrical: The variation of electrical characteristics with the variation of the absorbed humidity strongly limits its use in the electrical sector.

- Chemicals: Resists alkali, inorganic compounds and solvents.

PA6.6+FV30% is an extruded polyamych polymer on a PA6.6 base modified with 30% fiberglass, in order to increase its workability and improve its mechanical qualities. As a result, it shows one of the highest wear and traction resistance ever; is exceptionally resistant to compression and bending. Excellent dimensional stability, even mechanical characteristics remain high as temperatures rise

Features:

- Wear resistance is among the highest among technopolymers.

- Compression and traction are high, fatigue resistance is excellent, as are general mechanical characteristics.

- Resistance to aging, it resists weathering and low temperatures well.

- Black.

Application:

- Mechanical: The material is particularly suitable for obtaining gears and mechanical parts with high resistances, which can work even in critical environments, such as construction sites, or on earthmoving machines without suffering wear.

- Food: It is not used in contact with food.

- Electric: Although limited with the variation of the absorbed humidity, the electrical characteristics vary; however, mechanical and weather resistances are required.

- Chemicals: Good resistance to alkali, inorganic compounds and solvents.

Natural cast polyamide 6. This method of production, i.e. direct polymerization in special molds, allows the production of large, high-quality semi-finished products. The general characteristics improve to become similar to those of pa66.In fact, the material proves to be much better machined than extruded polyamidic, all resistances (compression traction, wear, etc..) are higher. It also boasts greater resistance to mechanical stress over time

Features:

- Wear resistance, even for heavy use.

- Tensile and compression resistance, hardness is higher than that of Polamide 6, fatigue resistance is higher.

- It boasts a higher quality than extruded PA6 in all production thicknesses and diameters.

- Self-lubricating, the friction coefficient is low and in principle sliding does not require lubrication.

- Resistance to aging, it resists weathering well.

- Antistatic behavior related to moisture absorption.

Application:

- Mechanical: for the possibility of obtaining semi-finished products and semi-finished large pieces it is a material widely used in the mechanical industry for obtaining large diameter gears, cams, pulleys, wheels and wear guides, bearings, supports.

- Food: it cannot be used in contact with food.

- Electric: the variation of electrical characteristics with the variation of the absorbed humidity strongly limits its use in the electrical sector.

- Chemicals: good resistance to alkali, inorganic compounds and solvents.

Polyamide 6 cast modified with the addition, in high percentage, of special lubricants left in solution in the material

Features:

- Very self-clarifying, the coefficient of friction is low.

- Wear resistance, better than PA6.

- The tensile and compression values are similar to PA6 G while the impact resistance is higher and the elastic module is lower.

- Yellow.

- Antistatic behavior related to moisture absorption.

Application:

- Mechanics: for the excellent self-clarifying power, the high compressive and impact resistances, the possibility of obtaining semi-finished and semi-finished pieces of large dimensions is a material widely used for obtaining bushings and bearings of large diameter, pulleys, rolls and anti-usasure guides; for excellent abrasion resistance, in construction and earth handling machines it is used for guides, bearings, supports and high-strength skates, etc.; in shipbuilding it is used to obtain sliding rollers, guides and bushings; for pulleys, wheels, sliding, etc.

- Food: it cannot be used in contact with food.

- Electric: the variation of electrical characteristics with the variation of the absorbed humidity strongly limits its use in the electrical sector.

- Chemicals: good resistance to alkali, inorganic compounds and solvents.

Polyoxytylene copolymer commonly called acetal resin boasts exceptional workability and dimensional stability. The POM-C – Delrin – has superior characteristics of workability and stability (very narrow processing tolerances for a plastic material) that make it increasingly irreplaceable in the most diverse applications. This is why POM-C has space in all industrial sectors

Features:

- High fatigue resistance and effort over time.

- Excellent dimensional stability.

- Low friction coefficient.

- High compression resistance and impact resistance even at low temperatures.

- High chemical resistance to strong solvents, fuels and alkali; resistance to thermal and oxidative degradation.

- Excellent workability to machine tools.

- Good dielectric and insulating properties.

- Not permeable to gases, no microporosity.

- Natural color and black-blue.

Application:

- Mechanical: today it is one of the most used technopolymers for obtaining mechanical details such as bearings, cams, gears with low modules, sliding wheels, guides and medical details.

- Food: physiologically inert, it is used in contact with food, it can be used in water up to 80°C.

- Electrical: non-hygroscopic material excellent insulation.

- Chemicals: it is resistant to alkali and organic compounds; thanks to the good chemical resistances it is used for pump bodies, flanges, parts and chemical plants.

Semi-crystalline polymer of excellent quality. It has exceptional mechanical characteristics and has a very high dimensional stability and hardness and the coefficient of friction is very low; for this reason it shows excellent results in precision applications, even fast-cycle and high scrolling speed. Wherever there is a problem of wear and stability and dielectric over time this material is irreplaceable

Features:

- Low coefficient of friction and high wear resistance.

- Dimensional stability at both temperature and humidity.

- Compression resistance even at low temperatures.

- Excellent workability with machine tools.

- High fatigue resistance.

Application:

- Mechanical: given the low coefficient of friction it is a material particularly used for sliding, bearings, sleds, guides, etc. The exceptional dimensional stability makes it irreplaceable for precision pieces with narrow tolerances to be maintained even in humid environments with the presence of heat.

- Food: physiologically it is inert and widely used in the food machinery industry.

- Electric: the excellent dielectric characteristics maintained over time make it widely used for insulators or electromechanical and electronic applications.

- Chemicals: good resistance to acids and chlorinated solutions.

Semi-crystalline polymer of excellent quality. It has exceptional mechanical characteristics and has a very high dimensional stability and hardness and the coefficient of friction is very low; for this reason it shows excellent results in precision applications, even fast-cycle and high scrolling speed. Wherever there is a problem of wear and stability and dielectric over time this material is irreplaceable

Features:

- Very low coefficient of friction, suitable for “dry” uses.

- High wear resistance.

- Dimensional stability at both temperature and humidity.

- Excellent workability to machine tools.

- Food compatibility.

Application:

- Mechanical: given the low coefficient of friction it is a material particularly used for sliding, bearings, sleds, guides, etc.

- Food: it is physiologically inert and widely used in the food machinery industry.

- Electric: the excellent dielectric characteristics maintained over time make it widely used for insulators or electromechanical and electronic applications.

High standard semicrystalline polymer. Material with very high mechanical and thermal characteristics (up to 240°C). Excellent resistance to creep under load and wear, its coefficient of friction is quite low. the material has a very high dimensional stability

Features:

- High temperature, resists at 240°C (resistance values are heat sensitive).

- High resistance to gamma rays.

- Very high resistance to sterilization cycles.

- High dimensional stability.

- Good chemical resistance.

- Good abrasion resistance.

- Electrical insulation.

- Food compatibility.

Application:

- Mechanics: Dimensional stability at temperature is high, like heat resistance. The components obtained have a high wear resistance and are self-clarifying; it is used for high performance parts both at low and high temperatures such as gears, bushings, in the aeronautical, space industry.

- Electric: good dielectric and insulating properties.

- Chemicals: excellent chemical resistance.

Commercial polyethylene, it is usually the extruded type. Good chemical properties, high workability, in relation to low hardness, and economy are its main skills. Compared to the PE1000, it has less impact and wear resistance and less resistance to internal stresses

Features:

- Good chemical resistances typical of polyolefin materials.

- Impact resistance, good even at low temperatures.

- Low specific weight.

Application:

- Mechanical: the low friction coefficient and non-hygroscopicity make it suitable for bearings or other mechanical parts with low loads, even if they work in water.

- Food: physiologically inert is approved for use in contact with food by the various Bodies. It is a material widely used for this feature in the construction of food machines, pumps for food liquids, etc.

- Electric: excellent dielectric characteristics and weather stability make it use more and more in this sector.

- Chemicals: due to its high chemical resistance to acids and alkali it is used for components in the chemical industry.

Molecular weight polyethylene +/- 500,000 with good stiffness. Compared to PE with higher molecular weights, this type is more rigid so better usable for mechanical use. The coefficient of friction is low and the workability is very good

Features:

- High chemical resistances typical of polyolefin materials.

- Good impact resistance even at low temperatures.

- High abrasion resistance.

- Low friction coefficient.

- Low specific weight.

- Ease of processing.

Application:

- Food: physiologically inert it is approved for use in contact with food by the various bodies. it is a material widely used for this feature in the construction of food machines, pumps for food liquids, etc.

- Chemicals: due to its high chemical resistance to acids and alkali it is used for components in the chemical industry.

- Electric: excellent dielectric characteristics and weather stability make it use more and more in this sector.

- Mechanical: the low coefficient of friction and non-hygroscopicity makes it suitable for bearings or other mechanical parts with low loads even if they work in water.

Polyethylene with an average molecular weight of about 5 000 000 is much more resistant to repeated impact and has a lower coefficient of friction; this decisively improves wear resistance and dimensional stability

Features:

- High impact resistance even at very low temperatures.

- Low friction coefficient and good wear resistance.

- Low specific weight.

Application:

- Mechanical: the low friction coefficient and non-hygroscopicity makes it suitable for bearings or other mechanical parts with low loads, even if they work in water.

- Food: physiologically inert is approved for uses in contact with food by the various Bodies; it is a material widely used for this feature in the construction of food machines, pumps for food liquids, etc. .

- Electric: excellent dielectric characteristics and weather stability make it use more and more in this sector.

- Chemicals: due to its high chemical resistance to acids and alkali it is used for components in the chemical industry.

PolyVinylChloride is a material widely used for good chemical resistances. It is rigid, but mechanically not very durable, with a low cost.

It is easily workable, welds very well to hot air and is self-extinguishing. Used in the galvanic and chemical industry for tank or plant coatings. The low resistance to impact, heat and weather conditions limits its use for mechanical uses, even general. Material available in different colors, white, black, gray, red and transparent.

It is easily workable, welds very well to hot air and is self-extinguishing. Used in the galvanic and chemical industry for tank or plant coatings. The low resistance to impact, heat and weather conditions limits its use for mechanical uses, even general. Material available in different colors, white, black, gray, red and transparent.

Features:

- High chemical resistances.

- Higher hardness than polyolefins.

- Ease of processing both to machine tools and for hot welding or hot blade.

- Self-extinguishing material.

- Color gray, red, natural, black.

Application:

- Mechanical: It is also used for mechanical parts in corrosive environments; compared to polyolefins it has a higher tensile strength.

- Chemicals: The greatest use of PVC is in the chemical industry, due to its high resistance to acids and alkali and for rigidity it is used for components in the galvanic and petrochemical chemical industry for the construction of valves, flanges, gears, etc.

- Food: It is not used in contact with food.

- Electric: Good dielectric characteristics make it use in this industry.

Semicrystalline polymer belonging to the polyolefin family, has a very good resistance to chemical agents. Mechanically just above the polyethylene with which it shares in any case the substantial limitedness of mechanical properties. High impact resistance, but not at low temperatures. It has a good resistance to

acids for which it is used in the chemical industry for particular subjects of relatively low effort

Features:

- Good chemical resistance.

- Low specific weight and limited cost.

- Ease of processing both for machines and for hot welding.

- Available in grey RAL 7032, natural and black.

Application:

- Mechanical: It is also used for mechanical parts in corrosive environments; compared to high molecular weight polyethylenes, it has a higher tensile strength.

- Food: Physiologically inert, if natural in color, it is approved for use in contact with food.

- Electric: Used in the electrical sector thanks to its good dielectric properties.

- Chemicals: The greatest use of PP is in the chemical industry, due to good acid and alkali resistance and higher temperature resistance than PVC; it is used for components in the galvanic and petrochemical chemical industry for the construction of valves, flanges, gears, tanks, etc.

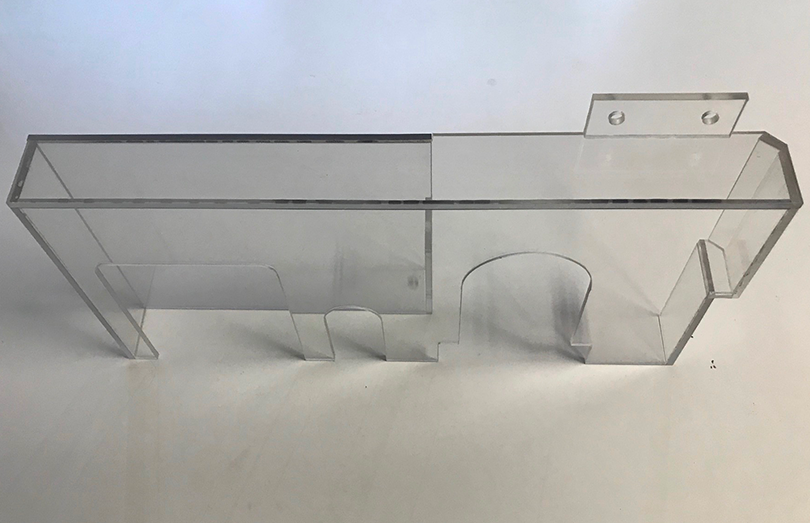

Polished and protected slab polycarbonate (Lexan/Makrolon) is commonly used for unbreakable protections and shelters often replacing glass. It shows, in fact, an excellent resistance to impact, discreet resistance to UV and weather. can be used for canopies it is advisable to check the stabilization to UV for this type of use in order to extend the useful life of the covers

Features:

- Transparency.

- High impact resistance.

- Dielectric properties.

- Very stable dimensionally.

- Very stable dimensionally.

- Good radiation resistance.

- Glossy finish.

Application:

- Mechanics: It is also used for precision mechanical parts when asking for good dimensional stability.

- Food: It cannot be used for food contact applications.

- Electric: Good dielectric characteristics; the most common uses of this material are from this sector.

- Chemicals: The use of PC in the chemical industry is not ideal given the low resistance to hydrocarbons.

Extruded polymethylmethacrylate, commonly called Plexiglass or acrylic. Unlike extruded, it has slightly higher mechanical and thermal properties. It is a material used in construction, modern architecture, boating, lighting, but also in industry, in relation to its excellent aesthetic qualities, its transparency, its colorability, flatness and optical purity, its thermoformability. It is quite easy to work with machine tools (cutting, turning, drilling, milling) and laser. It is perfectly polishable with the appropriate equipment. It is gluable

Features:

- Optical purity, flatness, colorability and polishability.

- Excellent resistance to natural aging and weather.

- Thermoformability and bondability.

- EC Food Certification 10/2011 – FDA.

Application:

- Construction: used for obtaining skylights, doors, windows, partitions, etc..

- Lighting: light signs, furnishing accessories.

- Industry: used for protections, transparent screens, etc.

Widely used fluorinated material for excellent chemical, electrical and thermal properties; the coefficient of friction is very low but the use for technical details is limited by low mechanical and wear resistances. PTFE can also be supplied with glass, carbographite, bronze and cemented surfaces

Features:

- Very low coefficient of friction: it is practically a lubricant in the solid state and is anti-adhesive.

- Excellent chemical resistances against almost all aggressive and practically insoluble even at high temperatures.

- Excellent resistance to both low and high temperatures, from -200 ° to 260°C.

- Excellent resistance to atmospheric and UV agents.

- Good thermal insulation power.

- High dielectric qualities, practically independent of temperature.

Application:

- Mechanics: The low friction coefficient makes it usable for very low load applications.

- Food: physiologically inert, it is used in this sector.

- Electric: Excellent dielectric characteristics, self-extinguishing and weather stability make it use more and more in this sector.

- Chemicals: Used for components in the petrochemical and chemical industry due to high chemical inertia.

It is an amorphous polymer with high thermal, electrical, mechanical properties typical of crystalline polymers. has high-level mechanical characteristics, when compared to other materials

Features:

- It resists high temperatures.

- Resistance to hydrolysis and steam.

- Mechanical tensile strengths, bending and module.

- Chemical resistances.

- Electrical properties.

- Transparent.

Application:

- Electric: excellent insulating power and dielectric properties make it irreplaceable in many applications such as circuit mounts, coils, insulators

- Mechanical: it is used for parts that must work both at low and high temperatures such as bearings, supports etc.

- Chemicals: the use is ideal given the high chemical and thermal resistances. Good chemical resistance to mineral acids, alkali and salt solutions. PSU is attacked by esters, chlorinated and aromatic hydrocarbons

- Food: it is physiologically inert so it is used for particulars in contact with even hot foods. It’s sterilizable repeatedly. The excellent chemical resistance makes it suitable for obtaining pump bodies, flanges, etc. for food liquids

Semicrystalline thermoplastic fluorinated polymer of vinylidene fluoride. It boasts excellent chemical resistances, a wide field of use in temperature, mechanical characteristics superior to PTFE and other fluorinated polymers (for hardness, traction, compression and abrasion resistance). PVDF resists aging well (bad weather and UV) and also significantly exceeds other fluorinated polymers in terms of resistance to ionizing radiation and high energy. The polymer boasts a very high degree of purity, is completely non-toxic and food compatible in all regulations. It also shows low permeability to the most common gases. Being hot-weldable with various technologies, its ease of implementation is remarkable

Features:

- High chemical resistances typical of fluorinated materials.

- Compared to other fluorinated polymers it boasts higher mechanical resistances in all values.

- Excellent resistance and stability both at low and high temperatures (up to 150°C).

- Good dimensional stability.

- Excellent resistance to aging, atmospheric agents, UV rays, radiation.

- Low flammability.

- Good wear resistance.

Application:

- Mechanics: The low friction coefficient makes it suitable for bearings even if they work in water.

- Food: Physiologically inert is approved for uses in contact with food; it is a material widely used for this feature in the construction of food machines, pumps for food liquids, etc.

- Electric: Excellent dielectric characteristics, self-extinguishing without the addition of alogens and stability to the weather make it more and more useful in this sector.

- Chemicals: Used for components in the petrochemical, chemical and electrical industries.